“From malt to beer”

Our small but smart 50 liter NANO brewery is developed to serve:

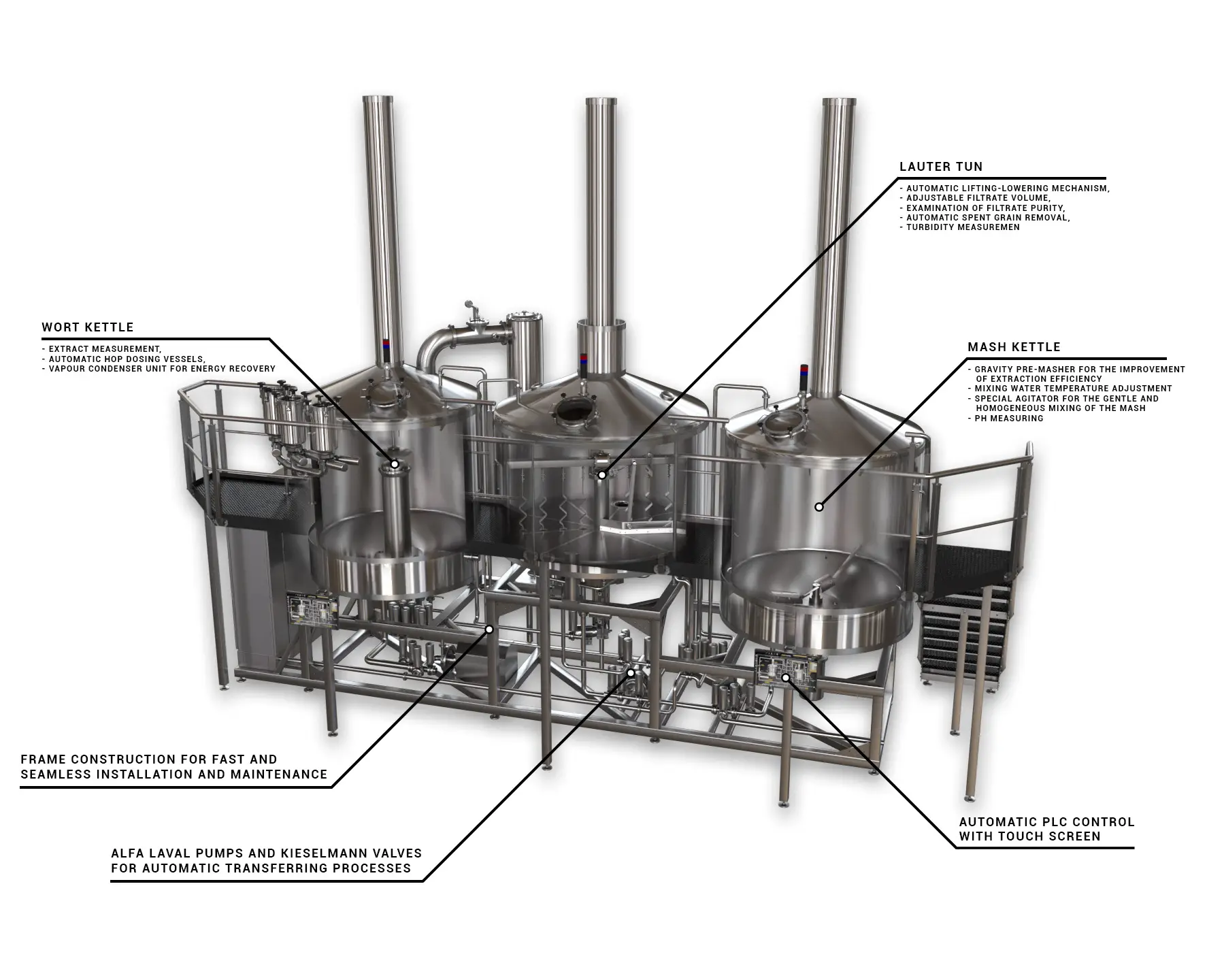

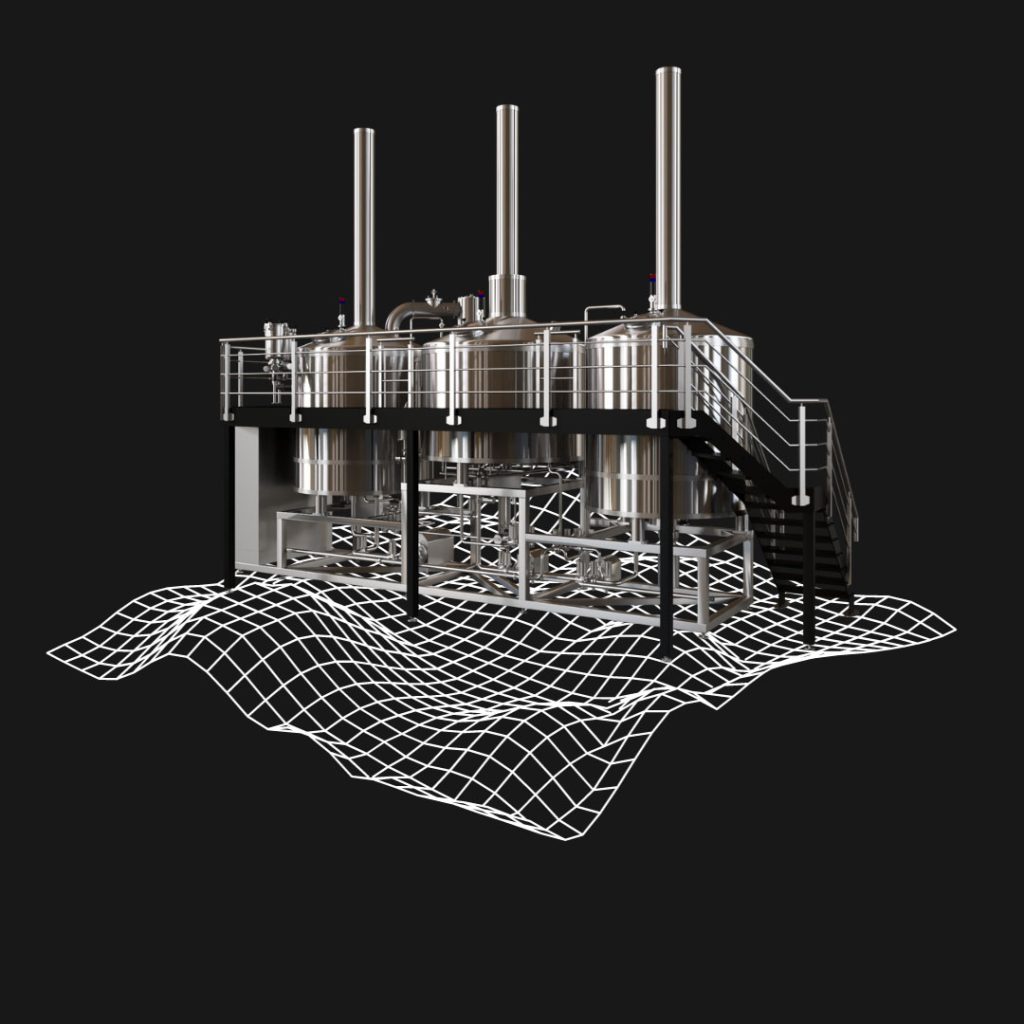

The NANO pilot brewery can produce 50-55 liter cast out volume depending on the beer style. Similar to our industrial systems it can be operated with our self-developed, user-friendly software, the ZIPMATIC. The modern, automated control system ensures proper step-by-step implementation of the processes of mashing, lautering, sparging, boiling with hops, whirlpooling, chilling and CIP-cleaning.

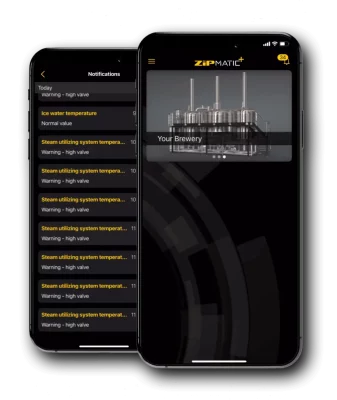

Automation is a critical part of a modern brewery striving to work effectively and efficiently. It liberates the brewmaster from routine monotonic work, releasing more time and energy for creative pursuits, stabilizes quality throughout batches and provides accountability for owners / investors. Our self-developed software, ZIPMATIC offers control technology and automated solutions for the brewing processes, from the arrival of malt until the packaging of the finished beer.

The entire software is developed by utilising the expertise of brewmasters and technologists with the aim to create an all-in-one, user-friendly operating platform which is convenient and understandable for all brewers, while at the same time allowing the flexibility to tailor it to the individual needs. The high level of automation ensures that every step of our operation and our recipes can be tracked, saved and thus reproduced to guarantee constant product quality.

Our self developed flash pasteurizer ensures the sterilization and preservation of the finished beer by destroying any deteriorating yeast and bacterial cells present in the beer with the help of heat treatment. In the pasteurization process, the beer is heated through a heat exchanger, held for a pre-set time span to reach the desired pasteurization units, and then cooled. Our flash pasteurizers are highly automated for better efficiency and process control and they are available with capacities from 1 000 to 10 000 liters per hour in two configurations:

ZIP KEG machines are available with different functions such as: only cleaning, cleaning and filling and only filling. Depending on the number of KEGs to be handled, we can offer 1 and 2 head constructions. These machines have a fully programmable operator interface for optimal cleaning flexibility and efficiency. The processes are automatic, except for the loading of the KEGs onto the working platform. The whole structure, including all of the single parts and pipelines are made of stainless steel with a construction that is easy to maintain. Each of our machines are conditioned with two tanks with an alkaline solution and an acidic solution, two independent pumps (to avoid any chemical cross contamination), automatic control (with a different set of sensors), optionally a steam generator for sterilization and counterpressure filling.

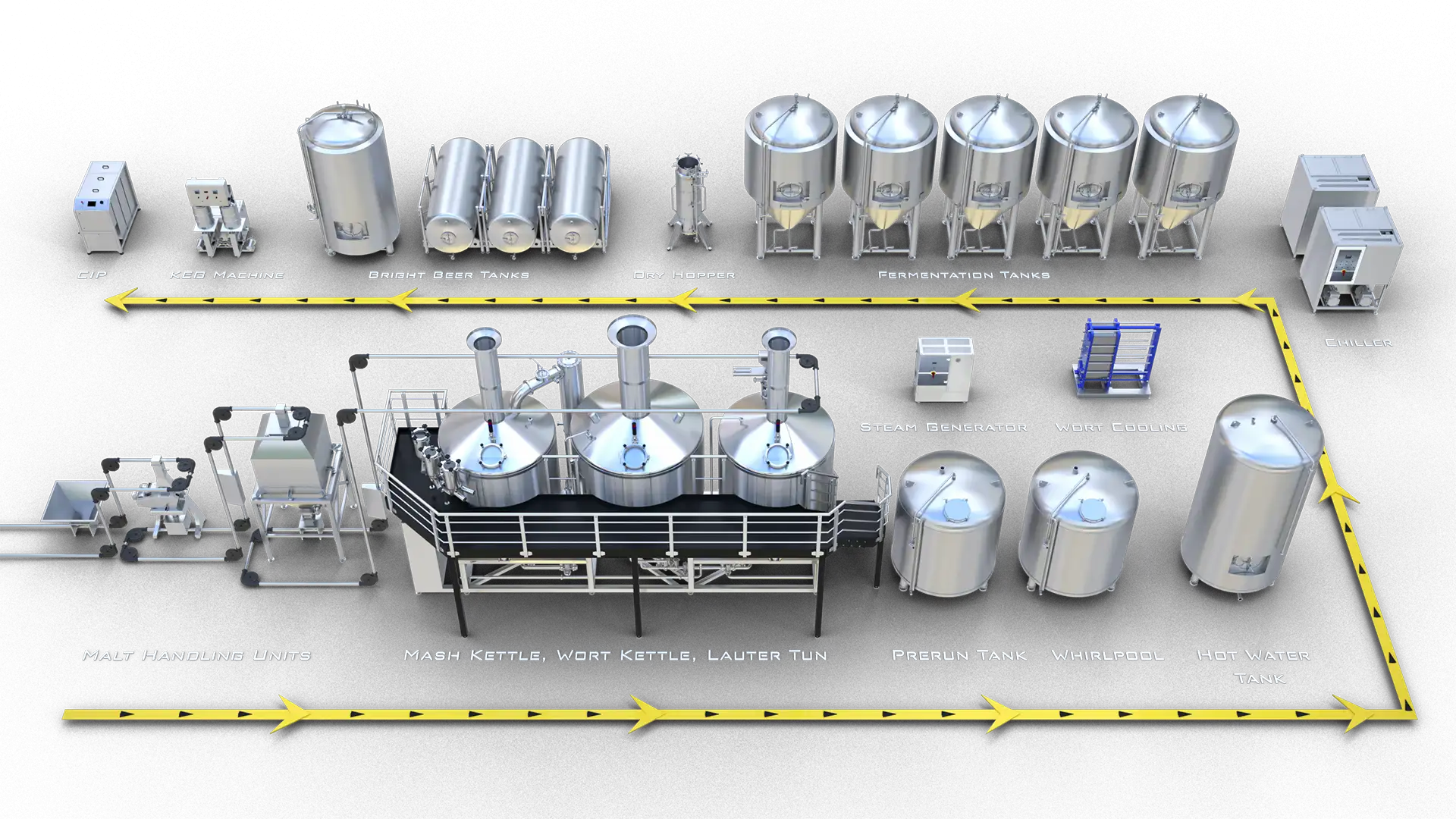

We are here to help you during the whole process of building your brewery step by step.