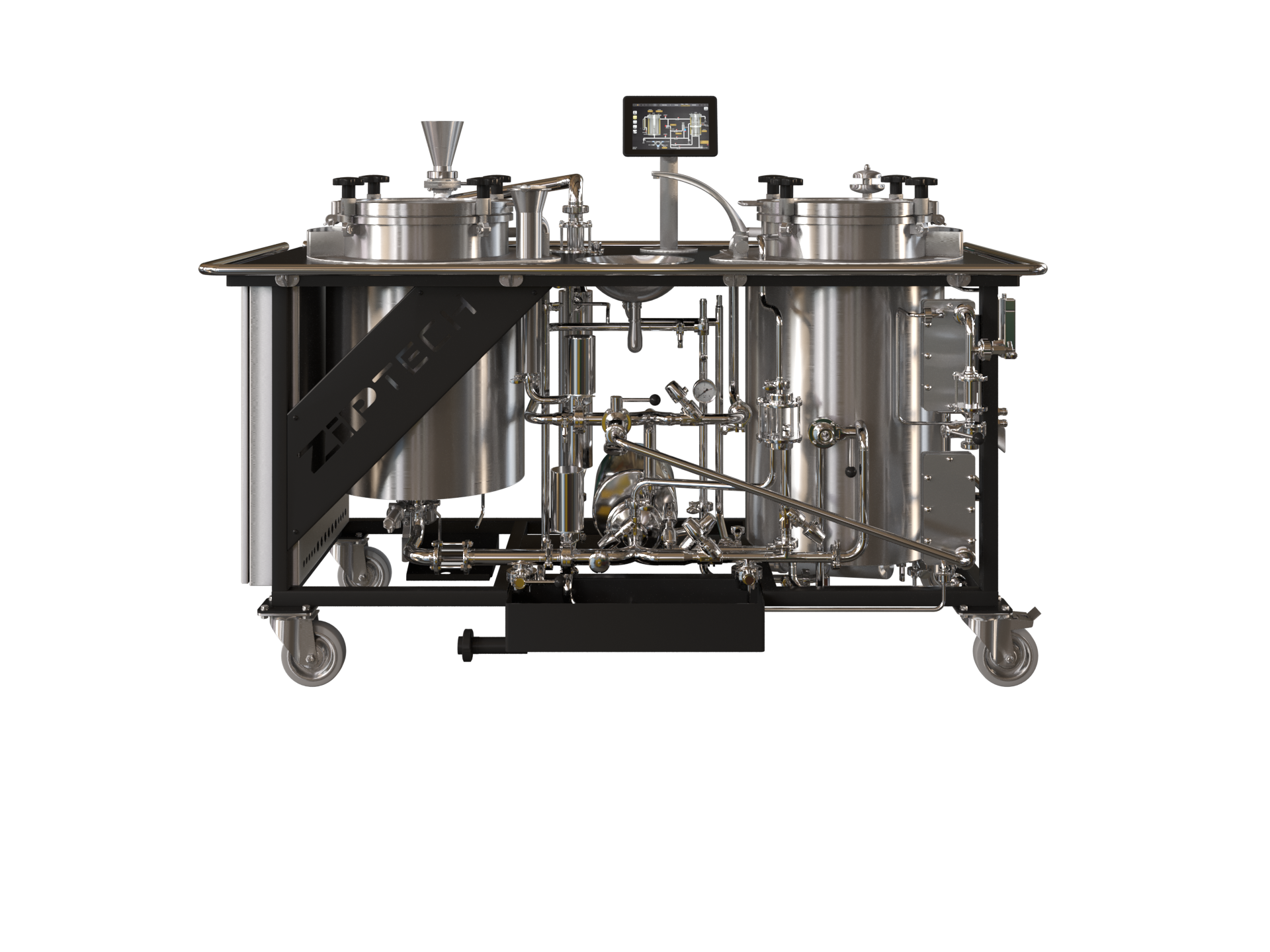

The NANO brewery can produce 50-55 liter cast out volume depending on the recipe and the beer style. Similar to our industrial systems it can be operated with our self-developed, user-friendly software, the ZIPMATIC. The modern, automated control system ensures proper step-by-step implementation of the processes of mashing, lautering, sparging, boiling with hops, whirlpooling, chilling and CIP-cleaning.